M.Sc. Lars Illmann

Kontakt

illmann@rsm.tu-...

work +49 6151 16-28907

fax +49 6151 16-28900

Work

L6|01 123

Otto-Berndt-Str. 3

64287

Darmstadt

Limited resources, cost and competitive pressures, tightening emissions legislation and the agreement to reduce anthropogenic greenhouse gas emissions on the one hand, and the increasing demand for personal mobility on the other, set the framework for current and future development goals in the automotive industry. The powertrain based on the gasoline engine is of central importance in this context. The main development goals are to increase thermodynamic efficiency while reducing emissions.

Therefore, the Institute for Reactive Flows and Diagnostics (Reaktive Strömungen und Messtechnik) aims to better understand the complex physical and chemical processes associated with internal combustion engines.

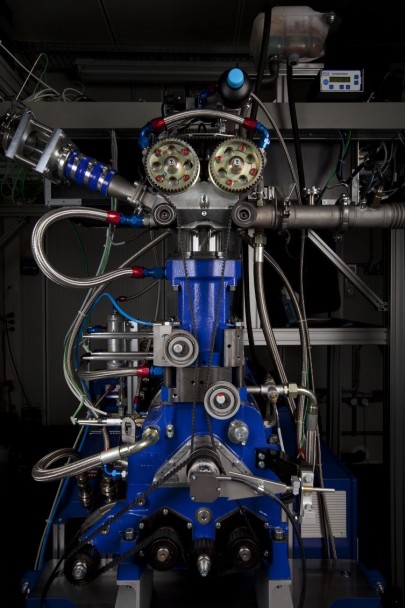

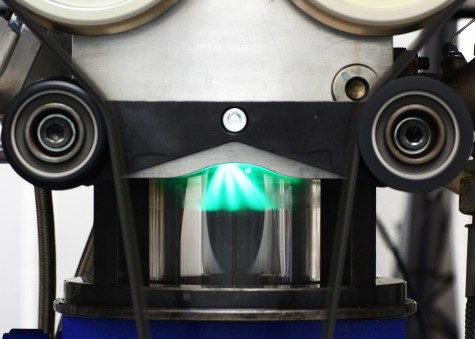

An optically accessible research engine with fused silica liner and piston top is used to investigate the combustion process in a SI or DISI engine. Different optical setups can be used to observe different characteristic combustion phenomena. Along with the acquisition of the temperature and pressure, advanced optical diagnostic techniques including particle image velocimetry (PIV), laser-induced fluorescence (LIF), thermographic phosphor thermometry (TPT), Mie scattering imaging, diffuse backlight illumination (DBI), and tunable diode laser absorption spectroscopy (TDLAS) are used to gain insight into the fundamental characteristics of combustion inside an engine.

The interaction between the operating conditions of the engine, engine geometry configuration, engine performance, and engine emissions are studied through analyses of the flow field, direct injection spray morphology, and the instantaneous surface temperatures of engine components.

Especially for the characterization of the internal mixture, data on the spray and its interaction with the turbulent flow field (Fig.: Spray Analysis), the local composition of the fuel-air mixture, the ignition and the subsequent combustion are required. The gained data will create an experimental-numerical benchmark platform to support the industrial use of scale-resolved simulations.

In addition to combustion diagnostics, optimizations are also carried out on the engine. Technical developments are planned, designed and conversions are carried out. Also the software can be rebuilt and optimized. Software development and designs thus play an important role.