Dr.-Ing. Michael Haas

Contact

The increasing scarcity of fossil fuels and the goal of CO2 neutral propulsion techniques demand new energy concepts within the field of automobility. The utilization of alternative fuels based on renewable energies constitutes one possible route to achieve this objective. As a suitable additive or substitute for diesel fuel, oxymethylene ethers (OME) have gained increasing attention. They can be produced using H2 from renewable energy sources, CO2 and water, thus enabling a closed CO2 loop. Furthermore, due to its molecular structure, the combustion of OME leads to significant reductions in soot emissions, allowing for more efficient inner-engine NOx reduction measures (e.g. higher exhaust gas recirculation rates).

Using blends of Diesel and OME however poses new demands for the diesel emission control systems downstream of the engine. The key component of such a system is a Diesel Oxidation Catalyst (DOC). Besides the efficient removal of CO and hydrocarbons from the diesel engine exhaust, its further purpose is to generate heat and to produce NO2, which allows for optimal operation of downstream components such as the Diesel particulate filter (DPF), NH3 selective catalytic reduction (SCR) catalyst or lean NOx trap.

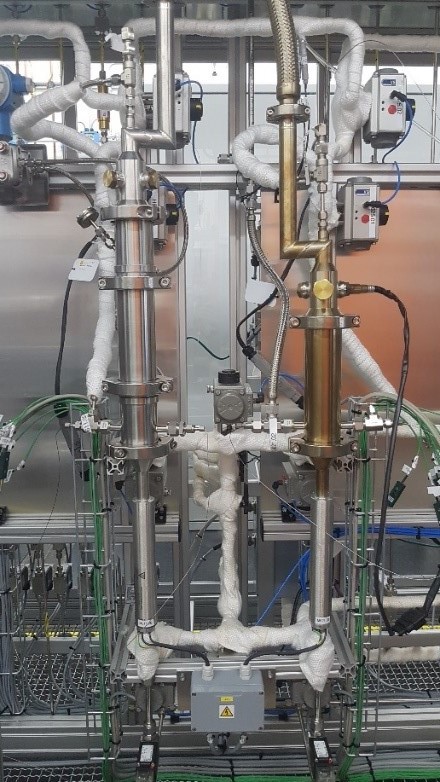

In a fully automated test rig, a synthetic exhaust gas is generated and passed through an DOC. Using different measuring techniques (e.g. FTIR, FID), the exhaust gas downstream of the catalyst is analyzed enabling to evaluate the catalyst performance under different exhaust gas conditions (composition and temperature). The test rig can be used for stationary measurements but also allows dynamic experiments to simulate real time driving cycles . The experimental investigations are assisted by numerical models, providing a deeper understanding of the underlying physical and chemical processes controlling the complex behavior of a DOC.