Dr.-Ing. Max Greifenstein

Contact

greifenstein@rsm.tu-...

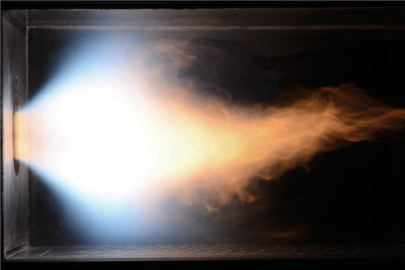

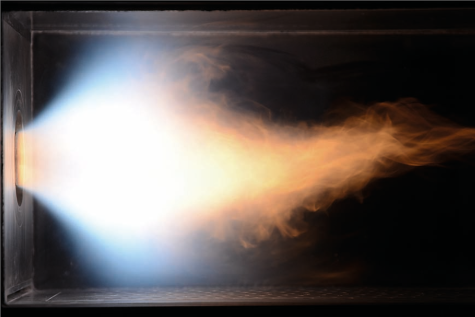

For the safe and reliable operation of modern aeroengines, combustor wall cooling is essential due to the high gas phase temperatures from combustion. Typically, these temperatures are in a range well above the peak temperature limit of metallic alloys. Despite extensive research on combustor wall cooling during the last 60 years, many open questions in the field of flame-cooling-air-interaction are still present. Within this work, this interaction is investigated using laser spectroscopic measurements in a generic optically accessible combustor at elevated pressure that mimics the boundary conditions of real aeroengine combustors.

Within this project, the interaction between cooling air and flame is investigated with regard to the influence of cooling air to the thermochemical state and important reaction rates using parametric variations of relevant boundary conditions, such as swirl, blowing ratio and staging. In a first step of the project, the influence of cooling air on the thermochemical state – and on the formation of an important pollutant – is investigated using gas phase thermometry (CARS) and quantitative carbon monoxide concentration measurements (CO-LIF).

In the next phase, mixture fraction imaging is employed to investigate the mixing behavior of cooling air and main stage. As tracer-LIF is combined with OH-LIF insights are gained in which zones of a premixed flame (preheat zone – reaction zone – exhaust) mixing occurs. In the last phase of the project, three LIF techniques (CH2O, OH, CO) are combined to further investigate the chemical interaction between cooling air and combustion. While the product of the OH and CH2O LIF signals yields a good correlation with the local heat release, the product of OH and CO gives information about the reaction rate OH + CO -> CO2 + H2O which is the major pathway of CO2 formation.