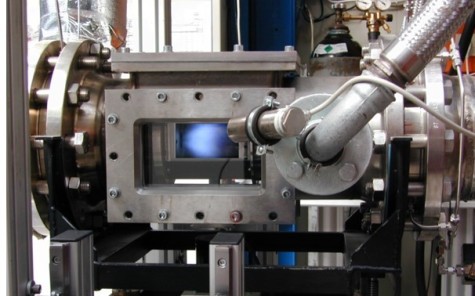

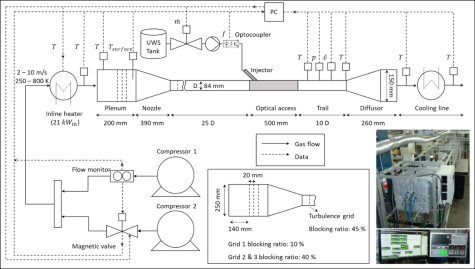

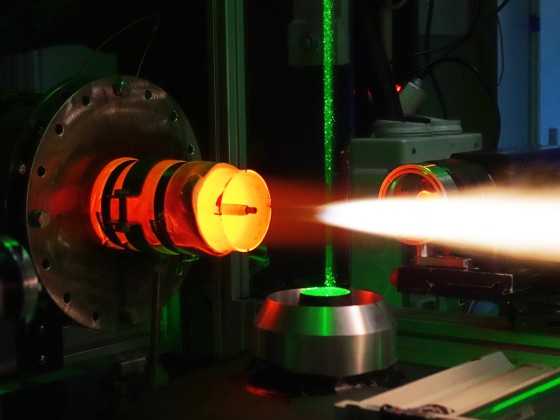

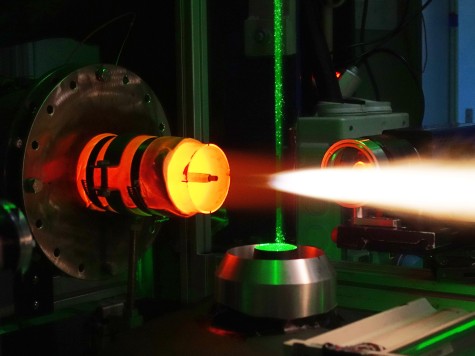

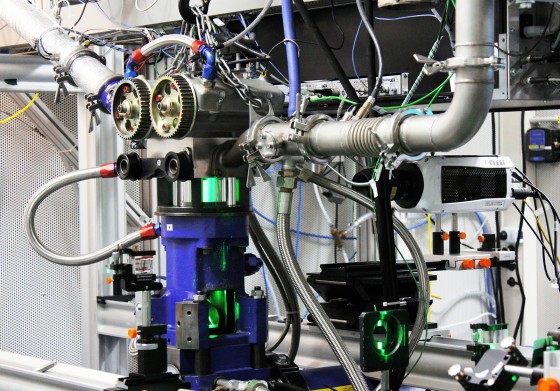

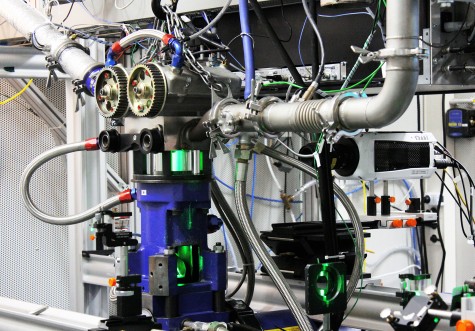

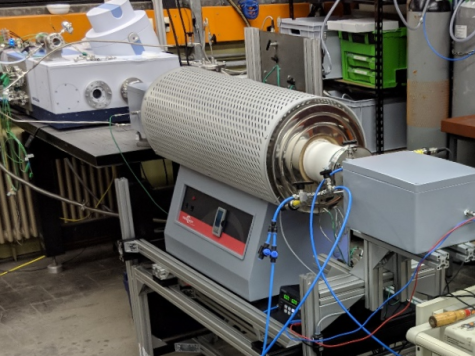

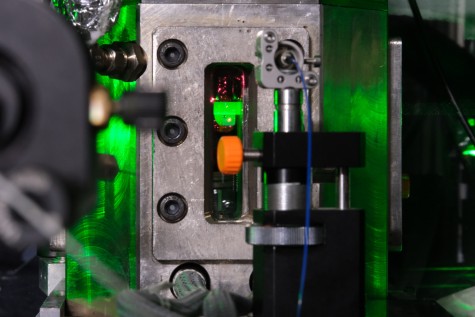

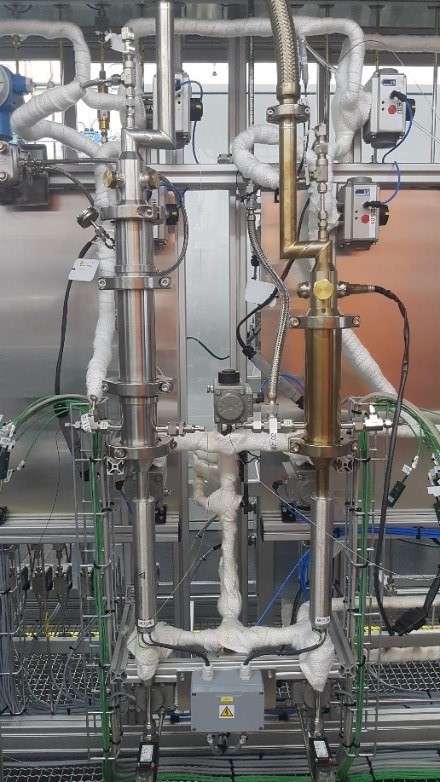

In a fully automated test rig, a synthetic exhaust gas is generated and passed through an DOC. Using different measuring techniques (e.g. FTIR, FID), the exhaust gas downstream of the catalyst is analyzed enabling to evaluate the catalyst performance under different exhaust gas conditions (composition and temperature). The test rig can be used for stationary measurements but also allows dynamic experiments to simulate real time driving cycles . The experimental investigations are assisted by numerical models, providing a deeper understanding of the underlying physical and chemical processes controlling the complex behavior of a DOC.

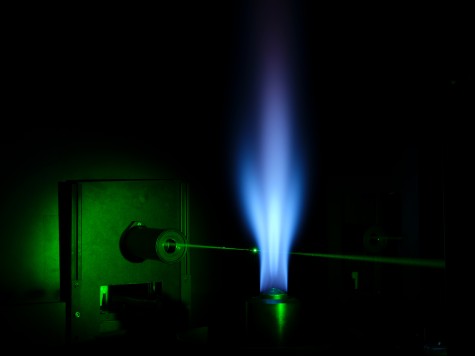

Picture: Michael Haas, RSM