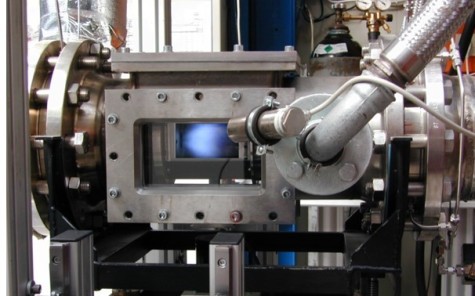

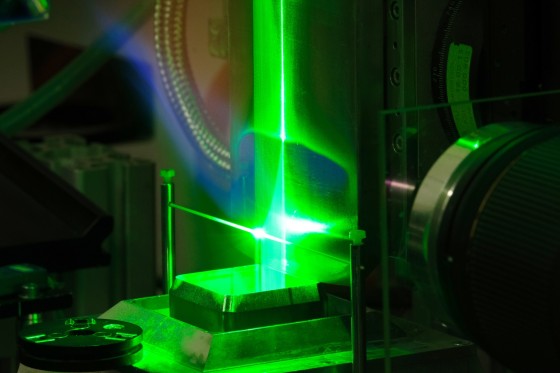

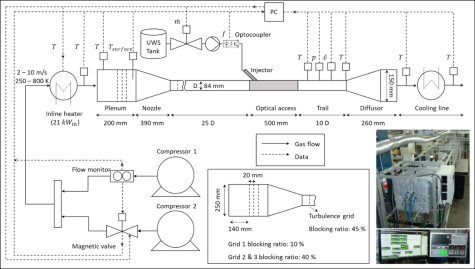

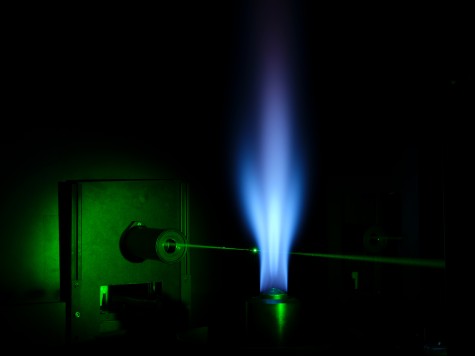

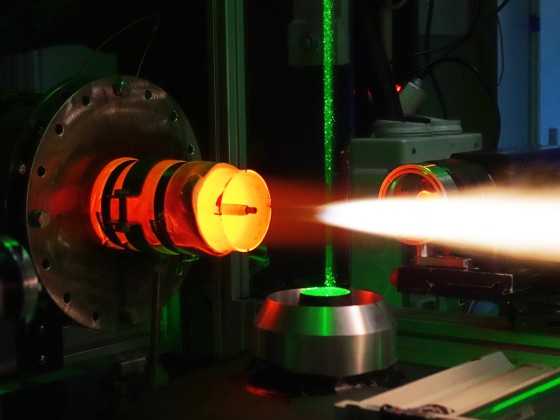

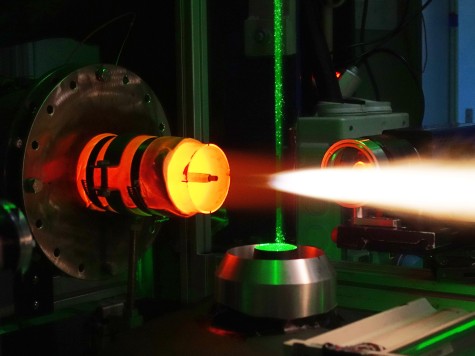

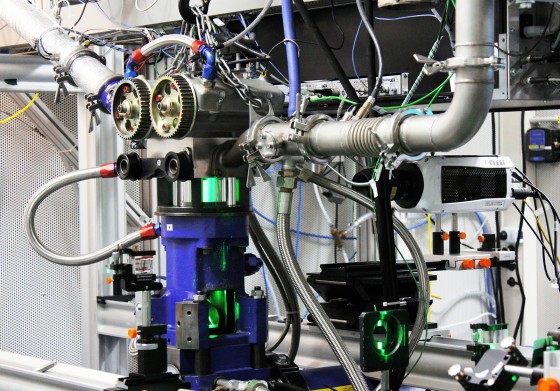

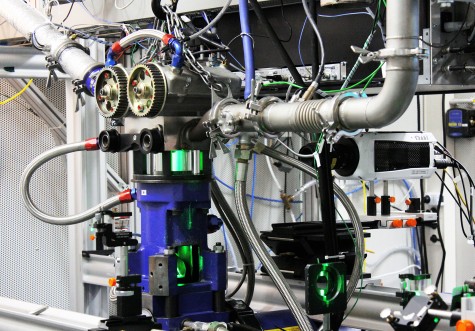

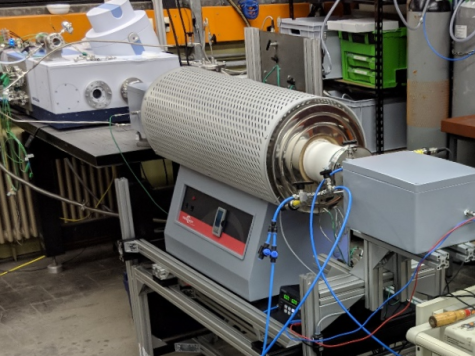

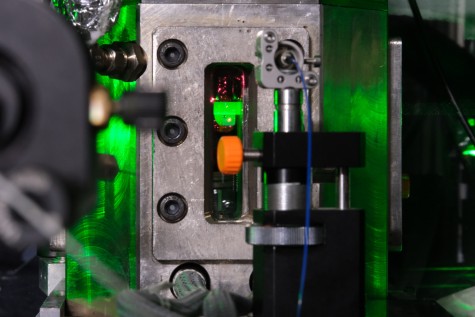

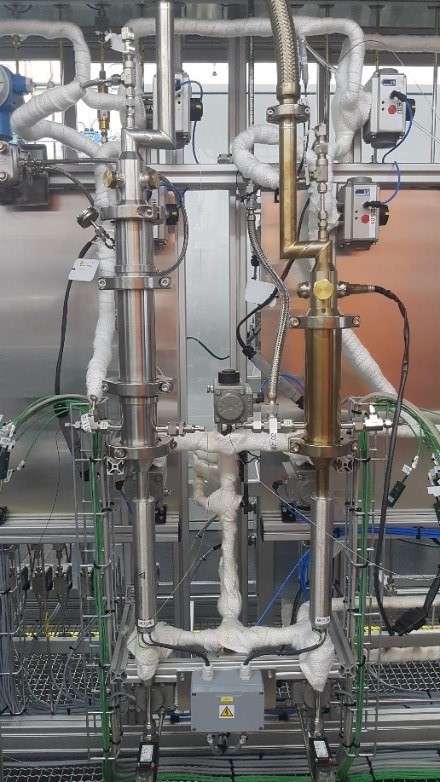

In einem vollautomatischen Prüfstand wird ein synthetisches Abgas erzeugt und durch einen DOC geleitet. Mittels verschiedener Messtechniken (z.B. FTIR, FID) wird das Abgas hinter dem Katalysator analysiert, um die Katalysatorleistung unter verschiedenen Abgasbedingungen (Zusammensetzung und Temperatur) zu bewerten. Der Prüfstand kann für stationäre Messungen eingesetzt werden, erlaubt aber auch dynamische Experimente zur Simulation von Fahrzyklen in Echtzeit. Die experimentellen Untersuchungen werden durch numerische Modelle unterstützt, die ein tieferes Verständnis der zugrundeliegenden physikalischen und chemischen Prozesse ermöglichen, die das komplexe Verhalten eines DOC steuern.

Bild: Michael Haas, RSM