Dr. Maria Angela Agizza

Kontakt

CLEAN-Gas project – Marie Curie actions

„Experimental investigations under different thermal efficiencies and practical engineering conditions using advanced Laser Diagnostics“

Gas turbine combustion, both for land use or jet engines face the evergreen challenge of achieving low pollutants emission and high fuel efficiency. For this purpose, present technologies are optimized continuously. This continuous improvement needs a deeper understanding of the fundamental physical and chemical processes, as well as a simple and flexible tool to investigate rapidly the effect of different operating conditions or variations of the combustion chamber design.

Residence Time Distribution (RTD) is connected to chemical reactors performance and widely used to optimize reactors design. The time species spend in the reacting system governs the completeness of the reaction, as well as the formation of certain pollutants [1].

RTD data can be further exploited as they support the design of an equivalent Chemical Reactors Network (CRN) model. In such a model, an appropriate network consisting of zero dimensional ideal flow reactors, namely the Plug Flow Reactor and the Continuous Stirred Tank Reactor, replaces the flow field and mixing properties [2].

This simplification of the fluid dynamics allows the use of detailed kinetics, to describe combustion phenomena in close to reality configurations.

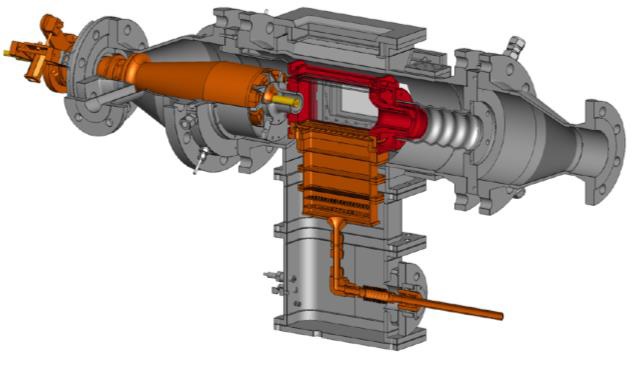

This approach enables the investigation of complex chemical processes occurring in different regions of the combustion chamber, to which several characteristics of combustor performance are related. Furthermore, once a well-designed equivalent CRN is achieved, it also allows performing a sensitivity analysis and studying the effect of parametric modifications of the system. In the present study, RTD measurements are carried out in a close to Single Sector Gas Turbine Model Combustor, Figure 1. The combustor reproduces the main characteristics of combustion phenomena in real apparatuses, and is conceived to fill the gap between laboratory-scale experiments and large-scale combustion devices.

Starting from the measured data and zonal modelling of the flow, a network of interconnected reactors is constructed to reproduce the mixing characteristic of the system in a simplified way. The network parameters are calculated by fitting the RTD of the network to the measured one. The different values of the fitting parameter point out the different mixing features due to the different investigated atmospheres.

The final aim of this analysis is to be able to exploit the model for analyzing parametric sensitivities of important parameters such as mass flow rates, equivalence ratio or fuel composition with regard to combustion performance.

Figure 1 – Section view of the test rig (upper image) and schematic view of the test rig with inlet conditions for standard operation point (lower image).

List of publication

[1] Bürkle, S., Becker, L. G., Agizza, M. A., Dreizler, A., Ebert, V., & Wagner, S. (2017). In-situ measurement of residence time distributions in a turbulent oxy-fuel gas-flame combustor. Experiments in Fluids, 58(7), 77.

[2] Agizza M. A., Bürkle S., Becker L. G., Greifenstein M., Bagheri G., Doost A. S., Faravelli T., Janicka J., Wagner S., Dreizler A. (2017). Reactors network modeling of a close to reality configuration using residence time measurements. Proceedings of the European Combustion Meeting, April 18-21, 2017.