Dr. Maria Angela Agizza

Contact

CLEAN-Gas project – Marie Curie actions

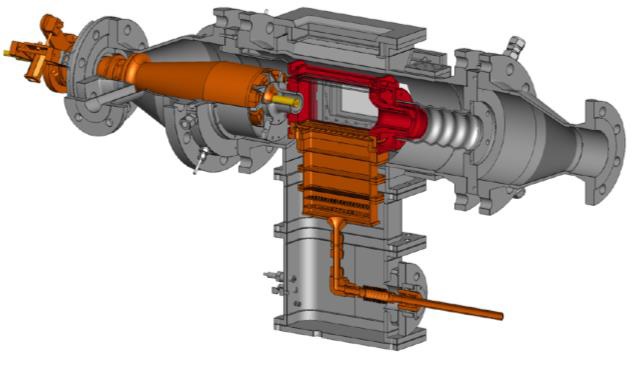

“Experimental investigations under different thermal efficiencies and practical engineering conditions using advanced Laser Diagnostics” Gas turbine combustion, both for land use or jet engines face the evergreen challenge of achieving low pollutants emission and high fuel efficiency. The trend toward engines downsizing poses the problem of a larger are where combustion reactions are quenched. Consequently, more species arising from incomplete combustion are formed, carbon monoxide, to name one. In this scenario, information about carbon monoxide formation in natural gas fuelled engines has to be gained. This is possible by performing quantitative carbon monoxide concentration measurements in a close to reality configuration. The amount of pollutant species inside the system gives insight about the pollutant formation pathways and what triggers those pathways. To this aim, a single sector gas turbine model combustor has been designed at Technische Universität Darmstadt (Figure 1), to mimic the relevant features in gas turbine combustion. Laser based diagnostics is applied, as it allows to obtain inflame information without interfering with the process.

The planned experimental campaign contemplates simultaneous Carbon Monoxide Laser-Induced Fluorescence (CO LIF, CO concentration) and Coerent anti-Stokes Raman Spectroscopy (CARS, temperature measurements). This campain is complemented by another one, in which Residence Time Distribution measurements are be carried out.

The distribution of the times the reactants spend in the system inside a system is a precious information.

The time species spends in the reacting system is important because it controls burnout of fuel and emission of certain pollutants [1].

RTD data can be further exploited as they support the design of an equivalent Chemical Reactors Network (CRN) model [2]. In such a model, an appropriate network consisting of zero dimensional ideal flow reactors, namely the Plug Flow Reactor and the Continuous Stirred Tank Reactor, replaces the flow field and mixing properties. This simplification of the fluid dynamics allows the use of detailed kinetics, to describe combustion phenomena in close to reality configurations.

Furthermore, once a well-designed equivalent CRN is achieved, it also allows performing a sensitivity analysis and studying the effect of parametric modifications of the system.

List of publication

[1] Bürkle, S., Becker, L. G., Agizza, M. A., Dreizler, A., Ebert, V., & Wagner, S. (2017). In-situ measurement of residence time distributions in a turbulent oxy-fuel gas-flame combustor. Experiments in Fluids, 58(7), 77.

[2] Agizza M. A., Bürkle S., Becker L. G., Greifenstein M., Bagheri G., Doost A. S., Faravelli T., Janicka J., Wagner S., Dreizler A. (2017). Reactors network modeling of a close to reality configuration using residence time measurements. Proceedings of the European Combustion Meeting, April 18-21, 2017.